1. Use principle

It it used on all kinds of offset machine. With the ink,first print image on paper, then transfer the image onto various materials by heat transfer press, especially for polyester fabric. Under high temperature, the ink will become gas and go into fabric.

2. Use Scope

Offset (one color, two color and four color machines)

3. Use Method

1.Be able to adapt to the demand for middle-speed or high-speed printing.

2.During the normal condition, use the ink on the machine directly.

4. The printing process just needs 3 steps

1. Print the image on paper, and normal paper is ok.

2. Put the printed paper on substrate, such as polyester and nylon fabric.

3. Put the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will be transfer printed from paper onto the substrate.

5. Suitable Fabrics

Polyester fabric, Triacetate fabric, Nylon fabric, Acrylic fabric, Polypropylene nitrile

6. Transfer Paper

Coated paper, offset paper,chrome paper and calendered paper.

Transfer paper should be 80-90 gr/m² with dimensional stability.

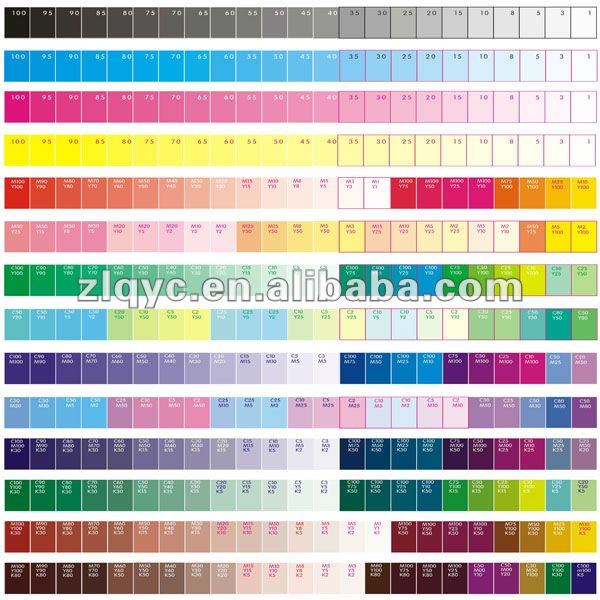

7. Colors

Magenta,Yellow,Cyan,Black.

8. Product Characteristics Product characteristics

* No Crust

a.Granula size is less than 5 micron.

b.No crust in 7 days at normal temperature.

* Safety

Passed SGS,DGM,MSDS,totally environment-friendly!

* Advantage

Good stability on the machine,clear dot reproduction,excellent ink-water balance.

Be able to adapt to the demand for middle-speed or high-speed printing.

During the normal condition, use the ink on the machine directly.

Our Sublimation Ink transferred into fabric

*P.S. please make samples before the final printing to confirm the exactly image.

9.Notice

Since sublimation ink belongs to gas shading, then the colour showing on paper and the colour showing on fabric are different. So when we make PS-plate, the CMYK ratio is different from normal offset plate making.

For example:

a. To get 50%C on fabric, the color on paper should be 30%C;

b. To make red PS-plate, the ratio is 100%M and 35%-40%Y;

c. To make blue PS-plate, the ratio is 100%C and 20%M;

d. To make green PS-plate, the ratio is 80%C and 90%Y;

e. If we want to get yellow like Asian skin, the ratio is 10%~11%M, 7%~8%Y and a little cyan.Cyan can be adjusted acooding to the requirement.

Transfer temparature

About 185~220°C

Transfer time

About 20~40 seconds

|

Product Name |

Sublimation Offset Ink |

|

Brand Name |

Zhongliqi |

|

Model |

HPA804,HPA604,HPA404,HPA204 |

|

Available Color |

Cyan , Magenta ,Yellow , Black |

|

Shelf Life |

3 years |

|

Printing Type |

Offset transfer printing |

|

MOQ |

1kg |

|

Package |

1kg/tin , 12tin/carton |

|

Certificates |

SGS , DGM , MSDS |

|

Supply Capability |

1000000kg per month |

The following is the transfer printing parameters for your reference

|

Name of fabric |

Transfer temperature |

pressure |

Time |

|

Polyester fabric |

205°C~220°C |

0.5kg/cm2 |

10~30 seconds |

|

Polyester deformation fabric low elastic |

195°C~205°C |

0.5kg/cm2 |

30 seconds |

|

Triacetate fabrics |

190°C~200°C |

0.5kg/cm2 |

30~40 seconds |

|

Nylon fabric |

195°C~205°C |

0.5kg/cm2 |

30~40 seconds |

|

Acrylic fabric |

200°C~210°C |

0.5kg/cm2 |

30 seconds |

|

Two acetate fiber fabric |

185°C |

0.5kg/cm2 |

15~20 seconds |

|

Polypropylene nitrile |

190°C~220°C |

0.5kg/cm2 |

10~15 seconds |

Dye degree:(European Standard)

|

Color fastness |

||||

|

Color |

Magenta(HPA604) |

Yellow(HPA204) |

Blue(HPA404) |

Black(HPA804) |

|

Rank |

5-6 |

6 |

4 |

4 |

10. Storage Indications and Packing

Products in their original unopened containers maintain their characteristics for two year if stored in a well ventilated place with a temperature between + 5° and + 40°C.Products opened, but immediately closed after use, have a shelf life of at least 12 months.